Quality Assurance

Quality Management System

Ergonomic Solutions (ES) is committed to always meeting or exceeding our customers’ expectations by delivering the highest levels of value, quality and service.

We operate the ISOWARE Quality Management System group-wide, covering all aspects of our businesses from development through manufacturing and sales.

This fully electronic management system is certified according to the requirements in the Quality Management System standard ISO9001: 2015 and the Environmental Management System standard ISO14001: 2015.

Having this management system in place ensures that we systematically improve the quality of our product and processes. Our focus is on providing a sustainable environment whilst meeting the requirements of our customers.

Learn more about our environmental policies.

The following locations are certified for both the ISO 9001:2015 and 14001:2015: Ergonomic Solutions Manufacturing A/S, Ergonomic Solutions Western, Ergonomic Solutions International, Ergonomic Solutions GmBH, Ergonomic Solutions SAS, Ergonomic Solutions Nordic AB and SpacePole Inc.

View our Quality Assurance ISO9001 and ISO14001 certificates (PDF format)

ISO2859-1 inspections are carried out as follows:

| Inspection Type | Measurement |

| Goods-in (sample inspection) | Standard Inspection level and an AQL (Accepted Quality Level) of 1.0 |

| Goods-out | Special Inspection level and an AQL (Accepted Quality level) of 0.65 |

Note on above

During the production process we have a number of defined quality inspections of critical-to-quality parameters on our products; for example, tension control and weight controls.

Ergonomic Solutions also report on a comprehensive range of Key Performance Indicators which allow us to monitor the quality of our production, shipping and logistics procedures.

We commit to report on a 12 months rolling average basis on the following KPI’s:

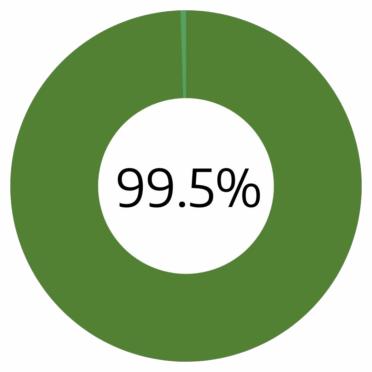

Quality Target Rolling Twelve Month Average

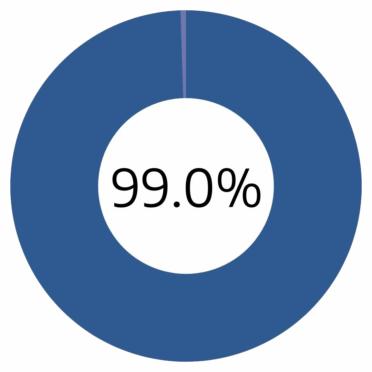

On Time Deliveries